COMPOSITE ROLLS

Tungsten carbide composite roll is a high-performance roll with high temperature resistance and thermal cracking resistance manufactured by high-tech methods. Correct roll pass profile processing, maintenance and reasonable use can greatly increase the rolling tonnage of the rolling groove and improve the rolling stability and rolling mill production operation rate.

INTRODUCTION OF CEMENTED CARBIDE

COMPOSITE ROLLS

Definition of Cemented Carbide Composite Rolls

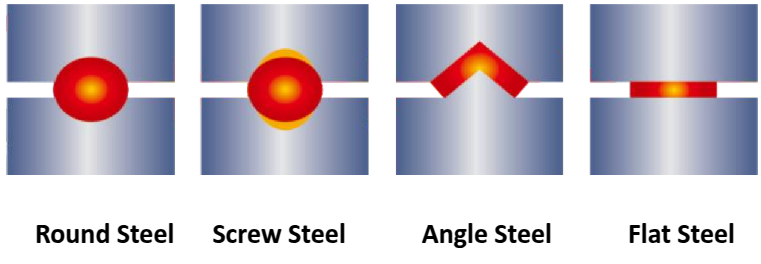

Composite roll is specially made by combining the cemented carbide roll rings with steel shaft, which is used for rolling round steel, ribbed steel, square steel, flat steel, angle steel and other profiles.

Scope Applications of Cemented Carbide Composite Rolls

The cemented carbide composite roll is suitable for the intermediate stands of the traditional rod mills, rod and wire mills and high-speed wire mills with rolling speed is 2-50m/s.

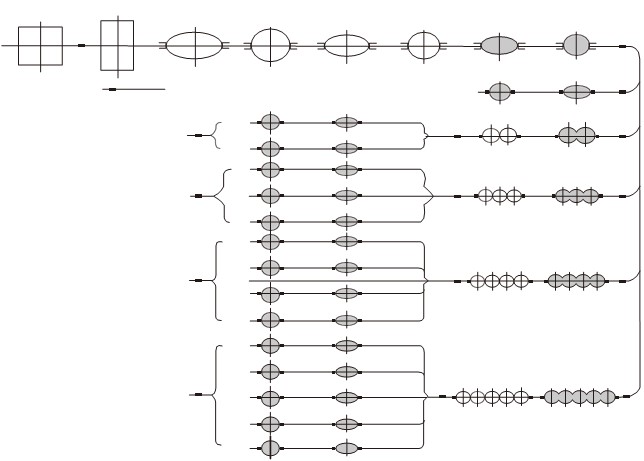

Traditional rod mills

It is used for product stands, pre-slitting stands and intermediate stands of traditional rod mills.

Wire & Rod mills

Used for the stands of finishing mills and intermediate rolling stands of rod and wire mills.

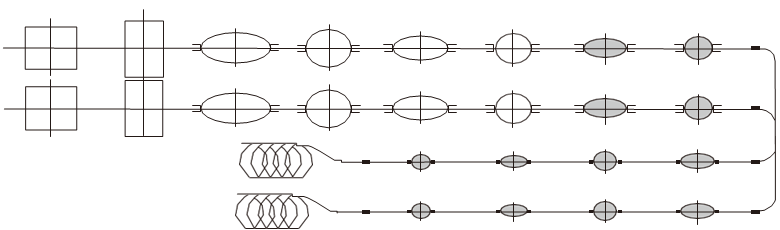

High speed wire rolling mills

Used in intermediate stands for high speed wire rolling mills.

Small profile mills

Used for Angle steel, square steel, flat steel of pre-finished product and finished product stands.

Advantages of Cemented Carbide Composite Rolls

- The quality of steel products is improved, and the surface quality and tolerance of rolled materials improved thoroughly. The negative deviation can be controlled more precisely.

- The change frequency of groove and roll, the downtime and the labour intensity can be reduced in rolling workshop. Increasing productivity and output can create greater economic benefit at the same time.

- Improve the yield of products.

- Greatly reducing the steel rolling cost per ton is an effective way for enterprise to reduce cost and increase benefit.

Composition and Characteristics of Grades for Cemented Carbide Composite Roll Rings

Cemented carbide is mainly made of tungsten carbide particles and metal binder (often cobalt), When needed , nickel, chromium, etc., is added in order to improve its hot cracking resistance and corrosion resistance. Different binder content and corresponding WC particle size can yield different cemented carbide grades.

Special Cemented Carbide Roll Rings Series

| Grade | Chemical Composition | Physical & Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| WC(%) | Co+Ni+Cr (%) | Densityg/cm³ | Hardness HRA | TRS N/mm² | Compressive Strength N/mm² | Young’s modulus KN/mm² | Thermal Conductivity | |

| PC20 | 77 | 23 | 13.25 | 83 | 2950 | 3100 | 450 | 70 |

| PC30 | 74 | 26 | 13 | 81.6 | 2920 | 2900 | 450 | 69 |

| PC40 | 70 | 30 | 12.65 | 80.9 | 2871 | 2700 | 400 | 61 |

| PC50 | 68 | 32 | 12.48 | 79.2 | 2700 | 2320 | 400 | 60 |

Special cemented carbide roll rings series: with optimized structure of WC, good hot cracking resistance , used in the stands of finishing rolling mills for rebar , rod and wire , which can greatly increase the amount of single pass rolling tonnage, reduce the labor intensity, so as to improve the production efficiency and obtain better economic benefits.

| Grade | Applications |

|---|---|

| PC20 | Good impact resistance and hot cracking resistance used in the front stands of finishing mills. |

| PC30 | Good wear resistance and hot cracking resistance, used in the stands of pre-finishing rolling mills for hot rolling rebar. |

| PC40 | Good impact resistance and hot cracking resistance, used in round bar finished products and rebar stands. |

| PC50 | Good impact resistance and hot cracking resistance, used in round bar finished products and rebar stands. |

General Cemented Carbide Roll Rings Series

| Grade | Chemical Composition | Physical & Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| WC(%) | Co+Ni+Cr (%) | Densityg/cm³ | Hardness HRA | TRS N/mm² | Compressive Strength N/mm² | Young’s modulus KN/m | Thermal Conductivity | |

| KTPL25R | 75 | 25 | 13.03 | 79.5 | 2600 | 3100 | 446 | 66 |

| KTPL30R | 70 | 30 | 12.73 | 79 | 2600 | 3000 | 425 | 57 |

General cemented carbide roll rings series: utilize Co-Ni-Cr as the binder phase, with high wear resistance and corrosion resistance and versatility

| Grade | Applications |

|---|---|

| KTPL25R | Good impact resistance, used in round bar finished and before the finished product stands. |

| KTPL30R | Good impact resistance, used in round bar finished and before the finished product and the slitting stands. |

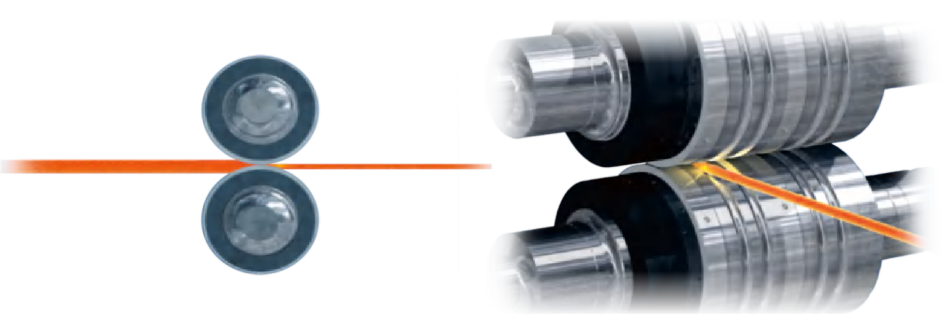

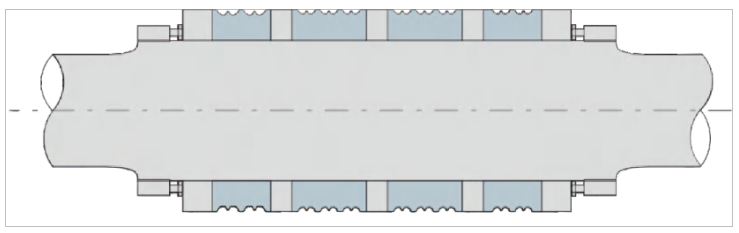

STRUCTURE OF CEMENTED CARBIDE COMPOSITE ROLLS

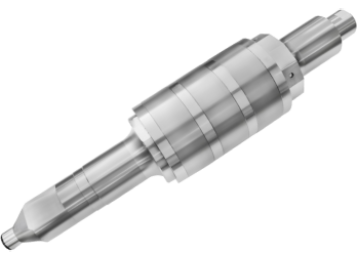

The cemented carbide composite roll is assembled by hydraulic axial compression combination technology with our own intellectual property rights. Hydraulic axial compression combination technology is a method to combine the roll ring and the roll shaft by applying a certain compression force in the axial direction of the roll ring. With the screw thread of hydraulic nut, the force generated by the hydraulic system is transformed into the tension force on the roll shaft, which causes the elastic tensile deformation of the shaft and causes the roll shaft to be compressed, and ensure the cemented carbide roll is not loose. Meanwhile, the roll shaft can be reused.

Supporting Technical services

- Service is available for the design, groove and notches machining of cemented carbide composite rolls.

- Various machining tools can be provided for machining cemented carbide composite rolls.

- A variety of assembly methods of composite rolls can be offered according to customer requirements.

- Various cemented carbide roll rings are available with diameters of ø300-450mm and thickness of 30-250mm for stands of bars and wires.